English

English

O'zbek

O'zbek

Azərbaycan

Azərbaycan

Қазақ

Қазақ

Latine

Latine

ລາວ

ລາວ

Burmese

Burmese

नेपाली

नेपाली

فارسی

فارسی

Українська

Українська

Ελληνικά

Ελληνικά

čeština

čeština

slovenský

slovenský

Română

Română

Zulu

Zulu

IsiXhosa

IsiXhosa

Монгол хэл

Монгол хэл

Кыргыз тили

Кыргыз тили

Shqiptar

Shqiptar

Hrvatski

Hrvatski

Беларус

Беларус

Esperanto

Esperanto

Српски

Српски

मराठी

मराठी

اردو

اردو

norsk

norsk

Indonesia

Indonesia

Polski

Polski

ไทย

ไทย

Nederlands

Nederlands

Italiano

Italiano

Tiếng Việt

Tiếng Việt

Deutsch

Deutsch

日本語

日本語

русский

русский

Português

Português

Español

Español

한국어

한국어

Svenska

Svenska

عربى

عربى

Gaeilge

Gaeilge

Türk

Türk

Pilipino

Pilipino

हिन्दी

हिन्दी

Suomi

Suomi

Dansk

Dansk

বাংলা

বাংলা

Malay

Malay

magyar

magyar

English

English

Canature Huayu Environmental Products Co.,Ltd

-

Softener Valve Water Softener Household Water Softener

-

PE Brine Tank for Water Softener 15 to 2000

-

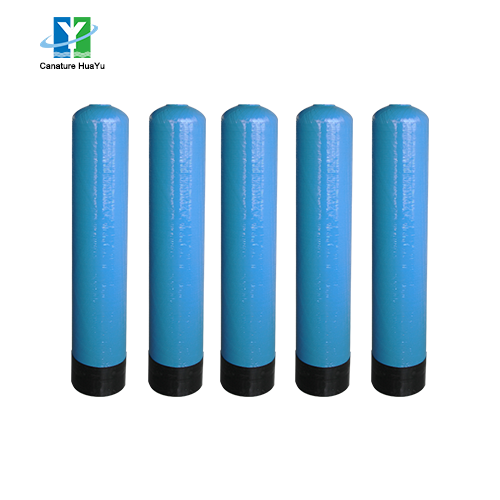

Water Treatment 150PSI FRP Water Filter Tank

-

Water Softening FRP Tank With Resin For Household

-

Softener FRP Pressure Tanks Industrial With Resin

-

PE Liner Water Filter FRP Tank

-

PE Liner Sand Filter Tanks Diameter From 6 Inch To 72 Inch

-

Industrial HDPE Sand Filter Water Softening FRP Tank

News

-

FRP Storage Tank Construction Promotes The Development Of Environmental Protection Industry

In order to ensure the safe production and operation of glass fiber reinforced plastic storage tanks, improve the service life of equipment and labor production efficiency, staff must conduct regular inspection and maintenance of glass fiber reinforced plastic hydrochloric acid tanks to prevent mechanical failures affecting production, and mechanical accidents causing casualties.

-

Testing method for resin content in FRP oil storage tank?

There may be resin in some FRP tanks. How to detect the resin content in the FRP storage? We have a simple method to detect, and the CANATURE HUAYU factory will introduce it in detail below.

-

FRP tanks are pursuing higher development needs

FRP tank is a non-metal composite tank in which resin and glass fiber are wound by a computer controlled machine. It has the advantages of corrosion resistance, high strength, long life, flexibility in design, and manufacturability. According to the characteristics of FRP tanks, FRP tanks are widely used in chemical, environmental protection, food, pharmaceutical, printing and dyeing and other fields, gradually replacing carbon steel and stainless steel in most mayor/market fields.

-

The many advantages of buying FRP tanks have been recognized by users

In daily life, it is more common to buy defective products when we buy things. Although now is the era of the rule of law, there are still many black-hearted factories. Especially for new products such as FRP Tank, when customers do not understand new high-quality materials, they use short-term benefits to put a large number of counterfeit products on the market, disrupting the market. The following is a detailed introduction by CANATURE HUAYU factory.

-

Performance characteristics and connection method of FRP oil storage tank

The performance characteristics and connection methods of FRP oil storage tanks are well known, and the details are little known. Therefore, the following knowledge should be popularized today to ensure that they will not be troubled by these problems during use.

-

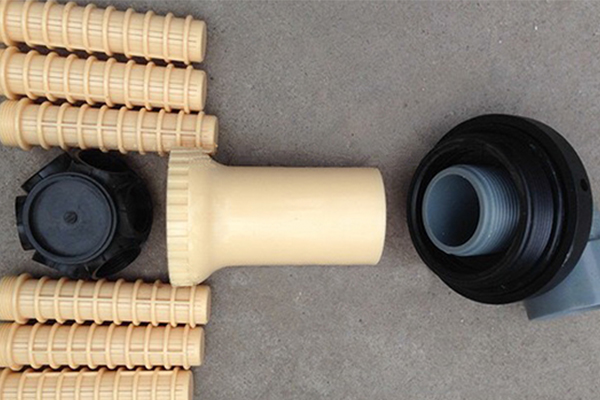

Instructions For The Installation Steps Of The Water Distributor In The Soft Water Tank

In order to distribute water evenly in the water treatment equipment, a suitable water distributor will be installed in the FRP water treatment tank, which plays the role of collecting and distributing water. Generally, there are upper water distributors and lower water distributors.

-

FRP Softening Resin Tank Control Instructions

The softening resin tank is a tank used to remove hardness ions such as calcium and magnesium in water and soften the water. The most common is the glass fiber reinforced plastic softening resin tank, which is often used in water treatment occasions such as laundry rooms, hotels, chemicals, textiles and so on.

-

Repair Steps After The Glass Fiber Reinforced Plastic Tank Is Damaged

FRP tanks are very popular in the water treatment industry. Although FRP tanks have high hardness and strong anti-corrosion ability, during the use process, other reasons will inevitably lead to the rupture of FRP tanks and water seepage.

-

The role of water softener salt tank

The water softener salt tank is mainly used to soak high-concentration salt water to reactivate the resin. At present, the most common water treatment technology for soft water dispensers on the market is ion exchange technology. The ion exchange resin of the training machine is usually a sodium sulfonate ion exchange resin. After the raw water to be treated passes through the resin, the Ca and Mg impurities in the water can be adsorbed on the resin to achieve the purpose of purifying the water.

-

Water Softener Backwash Process

The standard workflow of the water softener mainly includes five processes: work (sometimes called water production, the same below), backwashing, salt absorption (regeneration), slow flushing (replacement), and fast flushing. This article will mainly introduce the backwashing process of the water softener.