English

English

O'zbek

O'zbek

Azərbaycan

Azərbaycan

Қазақ

Қазақ

Latine

Latine

ລາວ

ລາວ

Burmese

Burmese

नेपाली

नेपाली

فارسی

فارسی

Українська

Українська

Ελληνικά

Ελληνικά

čeština

čeština

slovenský

slovenský

Română

Română

Zulu

Zulu

IsiXhosa

IsiXhosa

Монгол хэл

Монгол хэл

Кыргыз тили

Кыргыз тили

Shqiptar

Shqiptar

Hrvatski

Hrvatski

Беларус

Беларус

Esperanto

Esperanto

Српски

Српски

मराठी

मराठी

اردو

اردو

norsk

norsk

Indonesia

Indonesia

Polski

Polski

ไทย

ไทย

Nederlands

Nederlands

Italiano

Italiano

Tiếng Việt

Tiếng Việt

Deutsch

Deutsch

日本語

日本語

русский

русский

Português

Português

Español

Español

한국어

한국어

Svenska

Svenska

عربى

عربى

Gaeilge

Gaeilge

Türk

Türk

Pilipino

Pilipino

हिन्दी

हिन्दी

Suomi

Suomi

Dansk

Dansk

বাংলা

বাংলা

Malay

Malay

magyar

magyar

English

English

Canature Huayu Environmental Products Co.,Ltd

-

Softener Valve Water Softener Household Water Softener

-

PE Brine Tank for Water Softener 15 to 2000

-

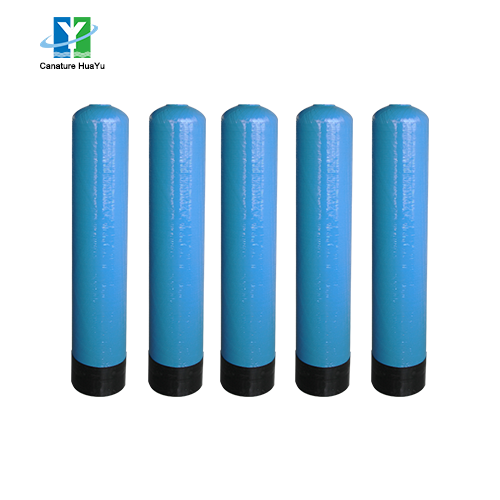

Water Treatment 150PSI FRP Water Filter Tank

-

Water Softening FRP Tank With Resin For Household

-

Softener FRP Pressure Tanks Industrial With Resin

-

PE Liner Water Filter FRP Tank

-

PE Liner Sand Filter Tanks Diameter From 6 Inch To 72 Inch

-

Industrial HDPE Sand Filter Water Softening FRP Tank

News

-

Brine Tank corrosion protection

Regardless of which method is used, the preservation of brine tanks is always an unavoidable problem. The traditional anti-corrosion construction of glass flakes is complicated and the quality is uneven, and it generally takes 1-2 years to re-corrosion.

-

What material is used for the salt water tank to prevent corrosion

During the use of salt water tanks, it is easy to cause tank corrosion problems. At present, there are many anti-corrosion coatings for tanks on the market, and the anti-corrosion effects are not the same. What materials are used for salt water tanks to prevent corrosion? CANATURE HUAYU factory introduces a coating with better anti-corrosion effect - Soleil CMI heavy-duty anti-corrosion coating.

-

The working principle of common water softeners

Hard water refers to water supplies that absorb large amounts of minerals (mainly calcium and magnesium) from the earth. If water is deficient in these minerals, it is described as "soft". Water can soften naturally (water sources from lakes and streams often soften naturally). Or softened by manual treatment, or softened by internal water treatment equipment such as the municipal water company or a water softener.

-

Basic knowledge of brine tank

A brine tank is exactly what its name suggests: a plastic tank filled with brine - saturated with brine or potassium. This salty water is used when the mineral tank needs to be backwashed, removing mineral particles and restoring the negative charge to the beads so they can continue to capture more minerals.